From Concept to Fabric: The Journey of Digital Fabric Printing

Posted by Support Team Backdropsource on

Have you ever wondered how the intricate designs and vibrant colors on modern fabrics come to life? The answer lies in digital fabric printing, a revolutionary process that is transforming the textile industry. This cutting-edge technology allows for detailed designs and stunning colors that traditional methods could never achieve. By understanding the journey of digital fabric printing from concept to finished product, we can appreciate its significant impact on textile production and design. Whether you're a designer, a business owner, or simply fascinated by textiles, exploring this journey offers a glimpse into the future of fabric creation and the endless possibilities it holds.

Exploring Digital Fabric Printing

Digital fabric printing is a modern method of printing designs directly onto fabric using digital technology. This process allows for intricate details and a wide range of colors, making it ideal for customized textile production. Unlike traditional methods such as screen printing, which require extensive setup and are limited in color and design flexibility, digital fabric printing is efficient, cost-effective for both small and large runs, and environmentally friendly due to its reduced waste and use of water-based inks. This innovative approach is transforming the textile industry by enabling rapid prototyping, quicker turnaround times, and the production of unique, high-quality fabrics.

The Design Phase: Laying the Foundation for Digital Fabric Printing

The design phase is crucial in digital fabric printing, starting with the creation and preparation of the design using advanced digital design software. This phase ensures precision and detail, with designers conceptualizing ideas and translating them into digital formats. Color management is vital to match digital designs with the final printed fabric accurately. High-resolution files are prepared for printing, ensuring every element is meticulously crafted. This phase sets the stage for producing high-quality, vibrant fabrics that meet the highest standards of accuracy and creativity.

The Digital Fabric Printing Process

The digital fabric printing process starts with converting the final design into a high-resolution file format like TIFF or PNG, typically at 300 DPI to ensure clarity. This file is then uploaded to the printer’s software for fine-tuning settings such as color profiles and print resolution, ensuring the design aligns perfectly with the fabric.

Specialized digital printers, designed to handle various fabrics with precision, are central to this process. These printers apply ink directly onto the fabric, eliminating the need for screens or plates and allowing for intricate designs and rapid production. Multiple print heads deposit ink in controlled patterns, ensuring accuracy even for complex designs. High-quality inks, both dye-based and pigment-based, are crucial for vibrant and accurate prints. Dye-based inks penetrate natural fibers like cotton and silk, while pigment-based inks sit on top and are more durable. Environmentally friendly water-based inks are commonly used, promoting sustainability and safety.

During printing, pre-treated fabric is fed into the printer, where the design is transferred with precision. The fabric must remain taut to avoid distortion. High-speed printers produce large volumes quickly without sacrificing detail or color accuracy. Post-treatment processes like steaming and washing fix the ink and enhance durability.

Choosing And Treating Fabric For Optimal Digital Printing

Selecting the right fabric is crucial in the digital fabric printing process, as the fiber content and weave significantly impact the print quality. Natural fibers like cotton, silk, and wool generally absorb dyes better than synthetics, resulting in more vibrant and detailed prints. Tightly woven fabrics offer a smoother surface ideal for high-detail designs, while looser weaves may suit certain aesthetic effects. Pre-treatment processes, including cleaning and applying a coating, prepare the fabric for optimal ink absorption. This involves washing to remove impurities, applying a chemical coating to enhance absorbency and thorough drying. Post-treatment processes, such as steaming to fix the ink, washing to remove excess chemicals, and final drying and finishing, ensure the durability and vibrancy of the print. Proper selection and treatment of fabric are essential to achieving high-quality digital prints. For professional results, consider Backdropsource, where meticulous attention to detail and quality ensure exceptional printed fabrics for all your needs.

Quality Control And Testing In Digital Fabric Printing

Quality control in digital fabric printing is crucial for ensuring consistency and high standards in every print. Robust quality control measures, such as color matching and resolution checks, help identify and rectify issues early in the process. Color matching involves comparing the printed fabric against the original design using tools like spectrophotometers to ensure accurate reproduction of colors, which is essential for maintaining brand integrity. Resolution checks involve inspecting prints under magnification to ensure fine details are clear and free from pixelation. Durability tests, such as wash and lightfastness tests, verify that prints maintain their quality over time. These comprehensive quality assurance procedures ensure that the final product meets customer expectations and upholds the reputation of the brand. For professional digital fabric printing, Backdropsource employs meticulous quality control to deliver exceptional results.

Wide-Ranging Applications Of Digital Fabric Printing

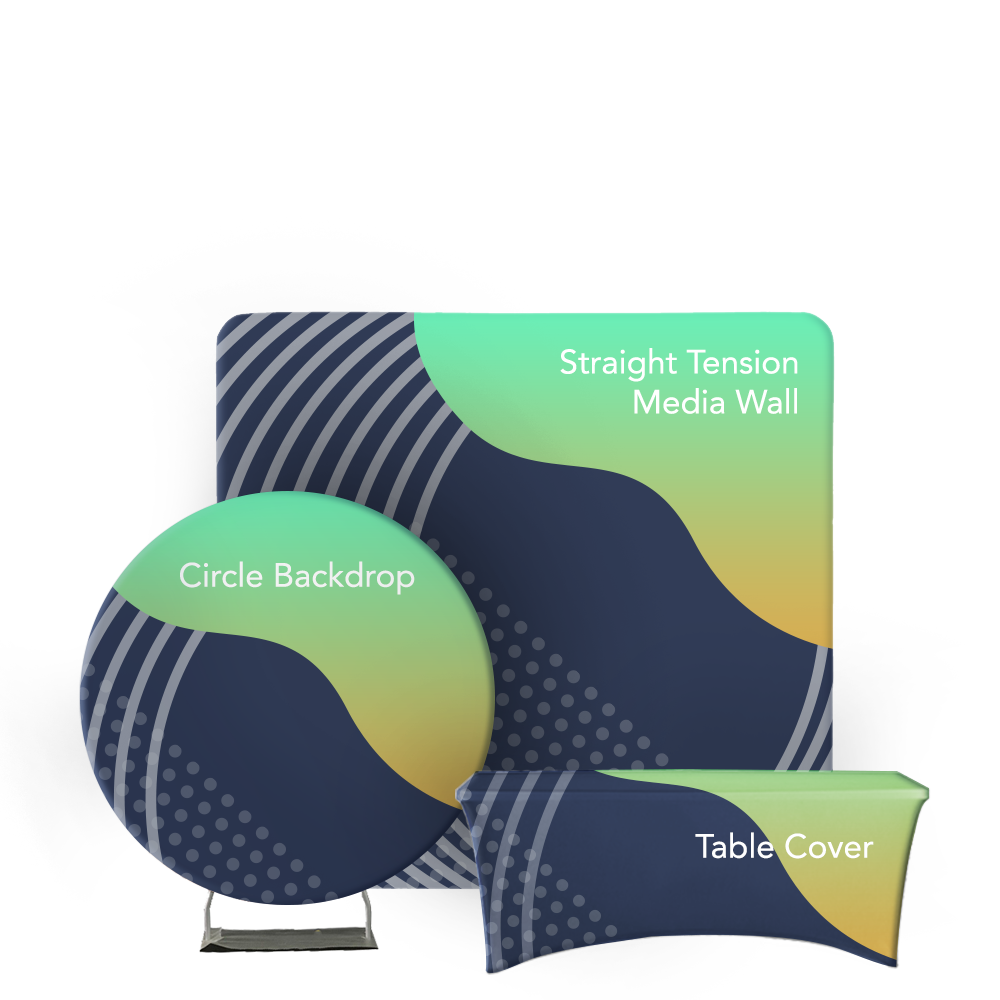

Digital fabric printing has revolutionized various industries, offering unprecedented flexibility and customization. In the fashion industry, designers use digital printing to create unique, intricate patterns on fabrics, enabling rapid prototyping and small-batch production without the high costs of traditional methods. This technology also allows for on-demand printing, reducing waste and enabling fast fashion trends. In-home decor, digital printing transforms spaces with custom-designed curtains, upholstery, and bedding that reflect individual styles and preferences. This level of customization was previously difficult to achieve with conventional printing techniques. The signage industry benefits from digital fabric printing by producing vibrant, durable banners and flags that withstand outdoor conditions. Real-world examples include high-end fashion collections showcasing digitally printed garments, custom home decor items tailored to specific interior design themes, and eye-catching outdoor banners for events and promotions. Digital fabric printing's ability to produce high-quality, customizable prints quickly and efficiently makes it an invaluable tool across these diverse applications.

Partnering With Backdropsource For Digital Fabric Printing Needs

For high-quality digital fabric printing services, Backdropsource offers a wide range of solutions to meet diverse industry needs. Whether you are in fashion, home decor, or signage, we provide customizable prints that bring your creative visions to life. With advanced printing technology and a commitment to excellence, we ensure vibrant, durable results that stand out.

Conclusion

The journey of digital fabric printing from concept to fabric showcases the transformative impact of this technology on the textile industry. By allowing for high levels of customization, precision, and efficiency, digital fabric printing is revolutionizing how we create and produce textiles. From the initial design phase to the final product, this process offers unparalleled opportunities for innovation and creativity. As the industry continues to evolve, digital fabric printing will undoubtedly play a crucial role in shaping the future of textile production and design.

For businesses and designers looking to leverage the power of digital fabric printing, partnering with Backdropsource is essential. Backdropsource offers high-quality digital printing services, ensuring vibrant, accurate, and durable prints. With a commitment to quality and innovation, we are the ideal partner for all your digital fabric printing needs, helping you bring your creative visions to life with precision and style.

sales@backdropsource.com

sales@backdropsource.com

+64 3 588 8033

+64 3 588 8033

USA

USA CA

CA AU

AU UK

UK IN

IN FR

FR ES

ES IT

IT DE

DE UAE

UAE

2 YRS WARRANTY

2 YRS WARRANTY